By Nicholas A. Veronico

In today’s climate of ever-shrinking budgets and the demand to do more with less, NASA’s Stratospheric Observatory for Infrared Astronomy (SOFIA) has become the beneficiary of two now-completed aircraft programs – the retirement of the 747 Airborne Laser Test Bed (ALTB) and the 747 Space Shuttle Carrier Aircraft (SCA). Millions of dollars worth of parts used to support those programs have been, or will soon be transferred to NASA to keep SOFIA in the air for many years to come.

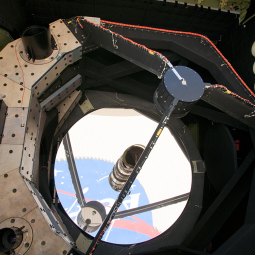

SOFIA is a highly modified Boeing 747SP (Special Performance) carrying a 2.5-meter (100-inch) effective-diameter, infrared telescope capable of making observations that are impossible for even the largest and highest ground-based telescopes. SOFIA makes observations at altitudes between 39,000- to 45,000-feet (12- and 14-kilometers), and captures images in the infrared spectrum between 0.3 and 1600 microns. The airborne observatory is a joint program between NASA (80 percent) and the German Aerospace Agency (DLR; 20 percent), and has a planned 20-year lifespan, thus the need for a sizeable spare parts inventory.

The End of a Technology Demonstrator

During the first Gulf War (August 1990–March 1991), Iraq launched a number of SS-1 “Scud” ballistic missiles at neighboring Israel and Saudi Arabia. The Scuds were fired from truck-mounted mobile launchers that would shoot the missiles and then pick up and drive to another location. To counter the launches, Air Force A-10 Thunderbolt II attack aircraft hunted for the scuds during the day while F-15E Eagles attempted to locate launch operations at night using infrared targeting pods and surface search radar. The massive effort expended by the Air Force in hunting for the scud’s mobile infrastructure demonstrated the need for a new method of combatting theater-deployed ballistic missiles.

U.S. military strategists envisioned a fleet of seven, highly modified Boeing 747s fitted with high energy lasers orbiting outside a hostile country’s borders patrolling for missile launches. During the boost phase of the missile’s ascent, the laser-equipped 747 would detect and lock onto the target, determine the weather between the target and the missile and adjust for any atmospheric conditions – such as rain or other water vapor, and then fire the laser destroying a missile.

To prove the theory, in 2001 the Department of Defense’s Missile Defense Agency put the concept out to bid and awarded a procurement contract to a Boeing-led team with the 747-builder providing the aircraft, Northrop Grumman the laser, and Lockheed Martin developing the fire control system and the nose turret. The result was the YAL-1 Airborne Laser Test Bed, a Boeing 747-400 freighter jam-packed with the infrastructure to initiate and fire a one-megawatt chemical oxygen iodine laser (referred to as COIL).

The directed energy-equipped airborne laser proof-of-concept turned science fiction into science fact on the evening of Feb. 2, 2010, when a solid fuel rocket was destroyed and again on Feb. 11, 2010, when a sea-launched, liquid fueled, ballistic missile was tracked and destroyed by the high-flying YAL-1. Both successful tests took place off the Southern California coast.

In subsequent months the Airborne Laser Test Bed suffered some setbacks and achieved additional successes. But having proven the technology, the program became a target for budget cuts. Coupled with the Defense Department’s vision of more powerful, yet smaller airborne lasers, funding for airborne laser was terminated in 2012. On Feb. 14 of that year, the YAL-1 made its last flight, from its home at Edwards Air Force Base, Calif., to the Air Force Materiel Command’s 309th Aerospace Maintenance and Regeneration Group, or AMARG, located at Davis-Monthan Air Force Base, outside Tucson, Ariz. Here the flying laser test bed was preserved and put into storage. During the course of its 15-year technology demonstration, the plane flew 206 missions, acquiring 250 cycles, and 954 flight hours.

The end of the Airborne Laser Test Bed program does not mean the end of aircraft fitted with directed-energy weapons. In January 2013, the Defense Advanced Research Projects Agency (DARPA) began studying the development of 150-kilowatt lasers through its High Energy Liquid Laser Area Defense System (HELLADS) program. DARPA envisions these weapons fitted to fighters and bombers enabling them to shoot down enemy air-to-air or ground-launched missiles. HELLADS is just one of a number of directed energy weapons programs under development today.

To Keep Others Flying

AMARG is affectionately called “The Boneyard,” but it is so much more. The AMARG facility sits on a 2,600-acre patch of Sonoran Desert, and although the term boneyard suggests a place where things go to die, this boneyard is an aviation parts warehouse on wings.

The boneyard is operated by AMARG and is home to nearly 4,000 military fixed- and rotary-wing aircraft, a variety of missiles, and a vast stockpile of parts primarily sitting inside the planes.

AMARG’s job is to provide a stockpile of parts to America and her allies’ military aircraft fleets, and store a variety of craft in various states of readiness ranging from those capable of returning to flight within days or weeks, to those undergoing the parts reclamation process that will eventually be scrapped once their carcasses are picked clean.

Having placed the YAL-1 into storage at AMARG’s facility, a new operator was sought for the test bed. With no takers and no economical way to reconfigure the YAL-1, the Missile Defense Agency decided to let AMARG do what it does best – return parts to the fleet to keep others flying.

“AMARG and Davis-Monthan Air Force Base were honored to publicly display the Airborne Laser Test Bed and share the platform’s impressive history with our tour patrons; however, the reclamation of parts to support the nation’s warriors is exactly why we began 67 years ago and we are proud to continue that mission,” said Col. Robert Lepper, AMARG commander.

While commercial airlines the world over have taken delivery of almost 1,500 Boeing 747s of all models, today the U.S. government operates only seven – two VC-25As that transport the President of the United States, four E-4B National Airborne Operational Center flying command posts, and NASA’s Stratospheric Observatory for Infrared Astronomy, or SOFIA.

Near the end of calendar year 2012, the opportunity to acquire additional parts was extended to the Air Force E-4 community and NASA. With a substantial amount of commonality between the various 747s models, the Missile Defense Agency, operators of the YAL-1, reached out to the other government users of the type to offer access to its stock of parts.

“Both NASA and the Air Force E-4 operators had a chance to select parts from our warehouses and identify items they’d like removed from the aircraft as well,” said Air Force Capt. Butch Wood, Airborne Laser Test Bed Disposition branch chief, Missile Defense Agency, Kirtland Air Force Base, N.M. “Based on their knowledge of the 747, each team was able to glean an approximation of what they wanted to save off the aircraft. From these requests we developed what we call ‘save lists.’ That’s where they take those lists and keep track of what leaves AMARG and what leaves the aircraft using their inventory system that they have in place.”

SOFIA Maintenance Chief Daryl Townsend led two missions to AMARG to remove parts from the ALTB, one in March 2013 and a second in July. Seven maintenance technicians were deployed on each trip, some overlapping. Team members included Michael Bondy, Rick Brewer, Jerry Dobbins, Arvid Knutson, James Mills, A. “Mitch” Mitchell, John Payne, Lindsay Rodriguez, Scott Rogers, Bryan Timar, and David Viera.

In an excellent demonstration of teamwork, the E-4B operators received the majority of the YAL-1’s control surfaces and exterior panels while NASA sought parts internal to the jet. “The removal process worked in such a way that when the E-4B crew removed their desired parts, that cleared the path for the NASA mechanics to access the actuators, motors, and other components they wanted inside the wing. It worked out pretty well,” said Wood.

“In winding down the Airborne Laser Test Bed program, we’re really trying to push the reutilization theme throughout. Now, we have scrapped a lot, but what we’ve scrapped is generally low-value parts,” said Capt. Wood. “I would say that with the exclusion of the ALTB mission parts, we’ve reutilized about 98 percent of the property value of the program, not counting the aircraft. A quick estimate of the aircraft components we’ve recycled, including the ALTB mission system, is around $15 million. Repurposing these parts enabled the government to save millions of tax payer dollars while allowing ABL hardware to continue benefitting the directed-energy research and 747 communities.”

The YAL-1 is slated to be scrapped at the end of calendar year 2013.

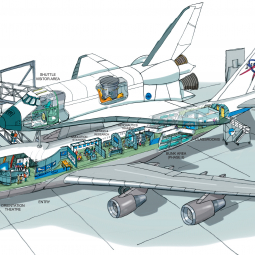

SCAs – Shuttle Carrier Aircraft

Two other government 747s were retired in 2012. The end of the Space Shuttle Program and the orbiters’ successful airborne delivery to museums across the country saw NASA’s pair of Shuttle Carrier Aircraft (SCA) permanently retired. During the orbiter delivery process, both SCAs were managed by the NASA Space Shuttle Transition and Retirement Program Office. This office determined the SCA’s final fates, and in doing so kept the SOFIA Program in mind.

One aircraft, N911NA was flown to the Dryden Aircraft Operations Facility in Palmdale, Calif., home of NASA’s SOFIA Program. Here, maintenance technicians will remove a number of internal parts that will be added to SOFIA’s spares inventory. It is hoped that once this process is complete, the aircraft can be displayed at a local aviation museum.

On May 2, 2013, the second shuttle carrier, N905NA, was transferred to Space Center Houston, the official visitor center for NASA Johnson Space Center, south of Houston, Texas. Here the SCA will be displayed with a full scale, highly detailed mock-up of a space shuttle mounted on top. Visitors will be able to tour both the SCA and the space shuttle while viewing a number of interactive, educational displays. This display is slated to open to the public in February 2015.

“We have access to both 747SCAs as they are very close in vintage to our 747SP,” said NASA SOFIA Platform Program Manager Brent Cobleigh. “We want to keep the external appearance of the SCAs intact for historical purposes while providing SOFIA with a substantial stock of spare parts. We’re primarily interested in engines, cockpit components, avionics, air conditioning packs, and other parts that might be useful in SOFIA’s future operations.”

Other 747SPs Have Contributed to SOFIA

In addition to parts from the YAL-1 and SCAs, the SOFIA program has acquired parts from two additional Boeing 747SPs. During the aircraft’s development, the aft section (Section 46 from the wing trailing edge to the aft pressure bulkhead) of an ex-United Air Lines Boeing 747SP was acquired to develop SOFIA’s modifications before metal was cut on the actual aircraft. The ex-United Air Lines 747SP (N141UA) was in storage at Ardmore, Okla. Here the aft section was surgically removed and shipped to L-3 Integrated Systems in Waco, Texas, where the SOFIA conversion was performed.

In November 2008, NASA acquired an ex-China Air Lines Boeing 747SP, N4508H, that was originally delivered to the Far East carrier on Sept. 15, 1981. China Air Lines operated the airliner until October 1991, when the aircraft was leased to Mandarin Airlines. Mandarin flew the jetliner until March 1997, when the plane was retired from service. It was stored at Las Vegas for a period before being flown to Marana, Ariz., where it became a source of spares for other flying 747SPs. NASA acquired the plane in November 2008, and began to part the jetliner out for its major structural components. Once removed, the parts – such as landing gear, horizontal and vertical stabilizers, control surfaces and flaps, and engine cowlings, were shipped to NASA Ames Research Center at Moffett Field, Calif., or other vendors, for overhaul. After refurbishing, these components will join SOFIA’s parts inventory.

“Parts obtained through the Missile Defense Agency, the Air Force’s AMARG, and the NASA Space Shuttle Transition and Retirement Program Office that are now in our inventory have set the SOFIA Program up for years of reliable operations,” said NASA SOFIA Program Manager Eddie Zavala. “Working with these organizations has enabled our program to establish a multi-million dollar spare parts inventory at a fraction of the cost.”

Author’s note: In addition to those mentioned in the article, the author would like to thank Dr. Dana Backman and Daryl Townsend (SOFIA); Beth Hagenauer (NASA Dryden) Lance Martin (L-3 Integrated Systems); Terry Pittman (309th AMARG); Debra Christman, Erin Saucier, and Harry Sinsheimer (MDA) for their assistance in preparing this article.